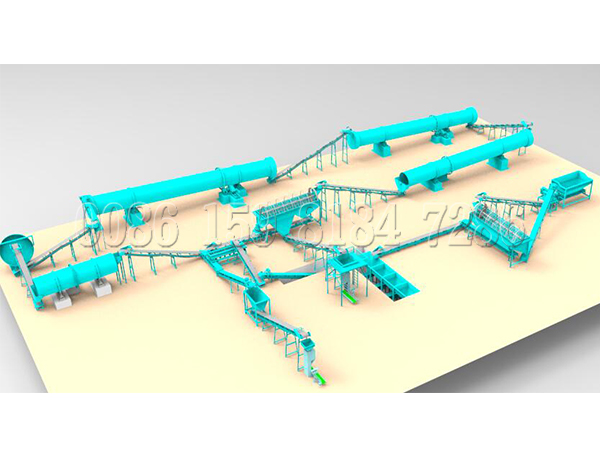

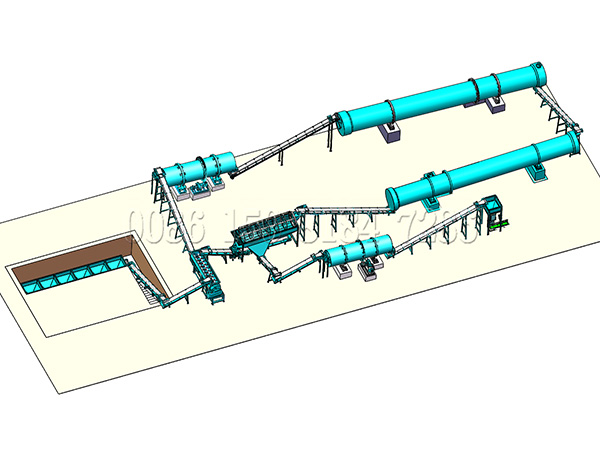

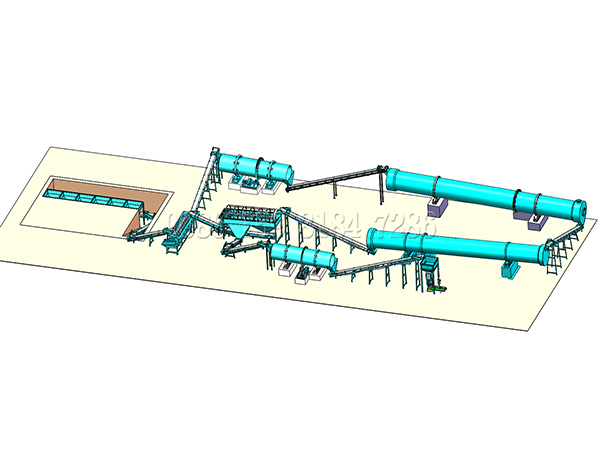

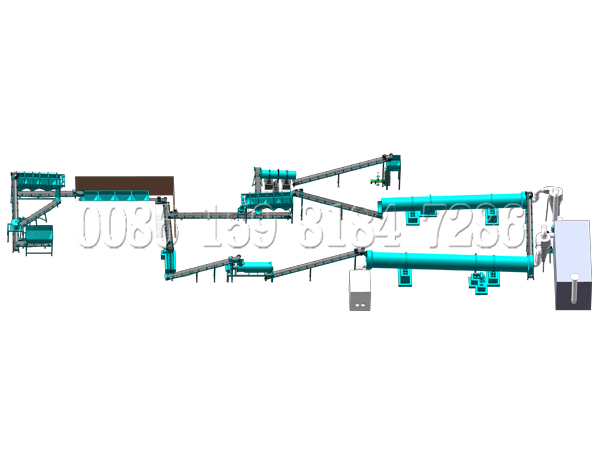

Chicken manure, pigeon manure, goose manure, quail manure and other poultry manure are a kind of superior organic fertilizer. The chicken manure content of nitrogen, phosphorus, potassium respectively are 1.63%, 1.54%, 0.085%. The Chicken manure must be thoroughly decomposed by decomposition agent before use, through which the parasite & its eggs and infectious bacteria go through inactivation and deodorization. The chicken manure production technology process is closely bound up with the equipment of its production line. Generally the complete set of equipment of fertilizer production line is compose of fermentation system, drying system, deodorization system, dust removal system, crushing system, mixing system, granulation system, screening system and packaging system. The production flow of chicken manure fertilizer is mainly as follows: raw material selecting→drying and sterilization→batching and mixing→granulation→cooling and screening→measure and package→finished product warehouse.

- Performance characteristics

- Efficient composite bacteria and its propagation technique.

- Advanced raw material blending technology and biological fermentation system.

- Superior fertilizer formula ( flexible design of formula according to the characteristics of local soil and crops)

- Reasonable secondary pollution (exhaust gas and odors) controlling technology.

- Whole set of processing equipment & design and manufacturing technology.

- Working principle

The production flow of chicken manure (pigeon manure, goose manure, quail manure) fertilizer is mainly as follows: raw material selecting→drying and sterilization→batching and mixing→granulation→cooling and screening→measure and package→finished product warehouse.

A more complex production flow of chicken manure (pigeon manure, goose manure, quail manure) fertilizer is as follows: first, put the organic raw materials (animal manure, house waste, deadwood & rotten leaves, biogas residue, waste culture) into semi-wet material mixer after fermentation. Second, add nitrogen phosphorous and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc) and make it meet the requirement of mineral element content. Again, put them into the mixer for stirring. Then add them into granulation machine. Finally, go through the process of drying, screening and package. If the products are not qualified, put them into granulation machine again.